Bal, Burak

Loading...

Profile URL

Name Variants

Bal, B.

Bal, Burak

Burak Bal

Bal, Burak

Burak Bal

Job Title

Prof. Dr.

Email Address

burak.bal@agu.edu.tr

Main Affiliation

02.06. Makine Mühendisliği

Status

Current Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

3

GOOD HEALTH AND WELL-BEING

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

0

Research Products

Documents

46

Citations

819

h-index

16

This researcher does not have a WoS ID.

Scholarly Output

49

Articles

36

Views / Downloads

1789/1012

Supervised MSc Theses

3

Supervised PhD Theses

3

WoS Citation Count

605

Scopus Citation Count

692

WoS h-index

13

Scopus h-index

14

Patents

0

Projects

0

WoS Citations per Publication

12.35

Scopus Citations per Publication

14.12

Open Access Source

18

Supervised Theses

6

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| International Journal of Hydrogen Energy | 7 |

| Materials Research Express | 4 |

| Journal of Engineering Materials and Technology-Transactions of the Asme | 4 |

| Materials Testing | 3 |

| Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing | 2 |

Current Page: 1 / 5

Scopus Quartile Distribution

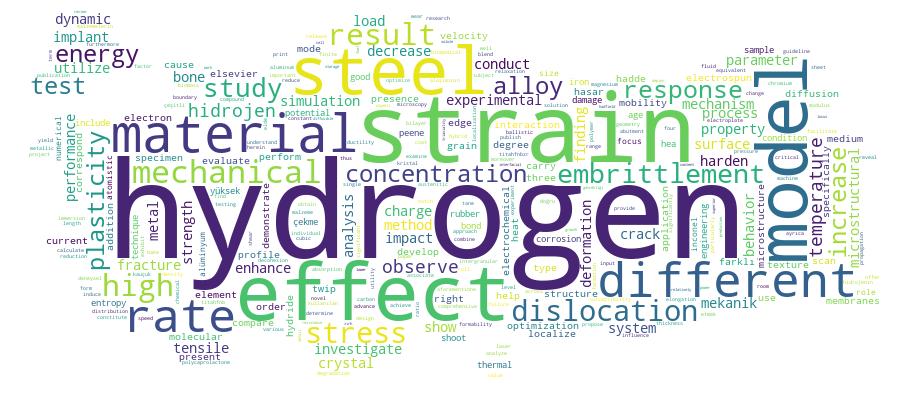

Competency Cloud

Scholarly Output Search Results

Now showing 1 - 10 of 49

Article Citation - WoS: 4Citation - Scopus: 4A Phenomenological Hydrogen Induced Edge Dislocation Mobility Law for Bcc Fe Obtained by Molecular Dynamics(Pergamon-Elsevier Science Ltd, 2024) Baltacioglu, Mehmet Furkan; Kapci, Mehmet Fazil; Schoen, J. Christian; Marian, Jaime; Bal, BurakInvestigating the interaction between hydrogen and dislocations is essential for understanding the origin of hydrogen-related fractures, specifically hydrogen embrittlement (HE). This study investigates the effect of hydrogen on the mobility of 1/2<111>{110} and 1/2<111>{112} edge dislocations in body-centered cubic (BCC) iron (Fe). Specifically, molecular dynamics (MD) simulations are conducted at various stress levels and temperatures for hydrogen-free and hydrogen-containing lattices. The results show that hydrogen significantly reduces dislocation velocities due to the pinning effect. Based on the results of MD simulations, phenomenological mobility laws for both types of dislocations as a function of stress, temperature and hydrogen concentration are proposed. Current findings provide a comprehensive model for predicting dislocation behavior in hydrogencontaining BCC lattices, thus enhancing the understanding of HE. Additionally, the mobility laws can be utilized in dislocation dynamics simulations to investigate hydrogen-dislocation interactions on a larger scale, aiding in the design of HE-resilient materials for industrial applications.Article Tuning Mechanical Performance of PCL Scaffolds: Influence of 3D Bioprinting Parameters, Polymer Concentration, and Solvent Selection(IOP Publishing Ltd, 2025) Ceylan, Saniye Aylin; Baltacioglu, Mehmet Furkan; Bal, Burak; Bayram, Ferdi Caner; Isoglu, Ismail AlperThe mechanical performance of three-dimensional (3D) bioprinted scaffolds is susceptible to printing parameters and material formulation. In this study, poly (epsilon-caprolactone) (PCL) scaffolds were fabricated using four different polymer concentrations (10%, 25%, 50%, and 75% w/v) to investigate how these variations, along with process parameters, influence mechanical behavior. Maintaining the structural integrity of bioprinted constructs requires careful optimization of polymer concentration and precise control over parameters such as printing speed, pressure, and infill density. Tensile tests were conducted to evaluate the effects of these variables. Among the tested conditions, a 50% (w/v) concentration allowed for a broader operational window, enabling fabrication across a range of printing speeds and pressures. At a printing speed of 5 mm s-1, PCL-DCM exhibited a Young's modulus of 39.0 MPa, while PCL-CF samples printed at 10 mm s-1 achieved the highest modulus of 32.0 MPa. Notably, when the printing speed was kept constant, applying higher pressures led to an increase in Young's modulus, suggesting that pressure plays a key role in enhancing scaffold stiffness. When comparing the 50% and 75% (w/v) polymer concentrations, the 50% (w/v) formulation stood out by offering both higher elongation and greater stiffness, which makes it particularly suitable for load-bearing applications. These findings provide a quantitative framework for optimizing extrusion-based bioprinting of PCL scaffolds, with implications for customized biomedical implants and regenerative medicine.Article Citation - WoS: 9Citation - Scopus: 12The Precise Determination of the Johnson-Cook Material and Damage Model Parameters and Mechanical Properties of an Aluminum 7068-T651 Alloy(ASME, 2019) Bal, B.; Karaveli, K. K.; Cetin, B.; Gumus, B.Al 7068-T651 alloy is one of the recently developed materials used mostly in the defense industry due to its high strength, toughness, and low weight compared to steels. The aim of this study is to identify the Johnson-Cook (J-C) material model parameters, the accurate Johnson-Cook (J-C) damage parameters, D-1, D-2, and D-3 of the Al 7068-T651 alloy for finite element analysis-based simulation techniques, together with other damage parameters, D-4 and D-5. In order to determine D-1, D-2, and D-3, tensile tests were conducted on notched and smooth specimens at medium strain rate, 10(0) s(-1), and tests were repeated seven times to ensure the consistency of the results both in the rolling direction and perpendicular to the rolling direction. To determine D-4 and D-5 further, tensile tests were conducted on specimens at high strain rate (10(2) s(-1)) and temperature (300 degrees C) by means of the Gleeble thermal-mechanical physical simulation system. The final areas of fractured specimens were calculated through optical microscopy. The effects of stress triaxiality factor, rolling direction, strain rate, and temperature on the mechanical properties of the Al 7068-T651 alloy were also investigated. Damage parameters were calculated via the Levenberg-Marquardt optimization method. From all the aforementioned experimental work, J-C material model parameters were determined. In this article, J-C damage model constants, based on maximum and minimum equivalent strain values, were also reported which can be utilized for the simulation of different applications.Article Citation - WoS: 33Citation - Scopus: 38Fracture Behavior of Novel Biomedical Ti-Based High Entropy Alloys Under Impact Loading(Elsevier Science SA, 2021) Gurel, S.; Yagci, M. B.; Canadinc, D.; Gerstein, G.; Bal, B.; Maier, H. J.This paper focuses on the mechanical properties and fracture behavior of newly developed body-centered-cubic structured TiTaHfNb, TiTaHfNbZr and TiTaHfMoZr high entropy alloys (HEAs) under impact loading as part of an effort to evaluate their potential utility as implant materials. The experimental findings showed all three Ti based HEAs have lower Young's modulus as compared to the conventionally used implant materials. Fractography analysis revealed that the TiTaHfNb HEA demonstrated significant ductility with the highest energy absorption capacity, while the TiTaHfNbZr and the TiTaHfMoZr alloys exhibited mixed mode fracture with relatively low ductility. Specifically, the reduction of ductility and energy absorption capacity under impact loading was attributed to the addition of Zr and Mo into Ti-based HEA system, which facilitates formation of additional dislocations in the microstructure due to increased lattice distortion. The current findings demonstrate that, from a mechanical point of view, the TiTaHfNb HEA could be considered as an alternative implant material for applications demanding high wear and corrosion resistance, such as hip or knee implants, and thus, warrant further investigation of the biomedical performance of this alloy.YArticle Citation - WoS: 14Citation - Scopus: 16Lowering Strain Rate Simultaneously Enhances Carbon- and Hydrogen-Induced Mechanical Degradation in an Fe-33Mn Steel(Springer, 2019) Tugluca, Ibrahim Burkay; Koyama, Motomichi; Shimomura, Yusaku; Bal, Burak; Canadinc, Demircan; Akiyama, Eiji; Tsuzaki, KaneakiWe investigated the strain rate dependency of the hydrogen-induced mechanical degradation of Fe-33Mn-1.1C steel at 303K within the strain rate range of 10(-2) to 10(-5)s(-1). In the presence of hydrogen, lowering the strain rate monotonically decreased the work hardening rate, elongation, and tensile strength and increased the yield strength. Lowering the strain rate simultaneously enhanced the plasticity-related effects of hydrogen and carbon, leading to the observed degradation of the ductility.Article Citation - WoS: 13Citation - Scopus: 17Effect of Hydrogen on Fracture Locus of Fe-16Mn Twip Steel(Pergamon-Elsevier Science Ltd, 2020) Bal, Burak; Cetin, Baris; Bayram, Ferdi Caner; Billur, ErenEffect of hydrogen on the mechanical response and fracture locus of commercial TWIP steel was investigated comprehensively by tensile testing TWIP steel samples at room temperature and quasi-static regime. 5 different sample geometries were utilized to ensure different specific stress states and a digital image correlation (DIC) system was used during tensile tests. Electrochemical charging method was utilized for hydrogen charging and microstructural characterizations were carried out by scanning electron microscope. Stress triaxiality factors were calculated throughout the plastic deformation via finite element analysis (FEA) based simulations and average values were calculated at the most critical node. A specific Python script was developed to determine the equivalent fracture strain. Based on the experimental and numerical results, the relation between the equivalent fracture strain and stress triaxiality was determined and the effect of hydrogen on the corresponding fracture locus was quantified. The deterioration in the mechanical response due to hydrogen was observed regardless of the sample geometry and hydrogen changed the fracture mode from ductile to brittle. Moreover, hydrogen affected the fracture locus of TWIP steel by lowering the equivalent failure strains at given stress triaxiality levels. In this study, a modified Johnson-Cook failure mode was proposed and effect of hydrogen on damage constants were quantified. (C) 2020 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved.Article Citation - WoS: 8Citation - Scopus: 11A Study of Different Microstructural Effects on the Strain Hardening Behavior of Hadfield Steel(Korean Soc Steel Construction-KSSC, 2018) Bal, BurakThe effects of the initial texture, velocity gradient, strain increment and type of interaction tensor on the strain hardening response of Hadfield steel were investigated. To observe their influences on mechanical response, crystal plasticity computations were carried out with the aid of the Visco-Plastic Self-Consistent (VPSC) algorithm. Specifically, uniaxial deformation response of Hadfield steel was modeled based on the experimental deformation response at a strain rate of 1x10(-1) s(-1) and corresponding Voce hardening parameters were calculated. The same Voce hardening parameters were utilized with different boundary conditions in the VPSC simulations to identify the roles of the aforementioned microstructural properties. The current results demonstrate the importance of these microstructural properties for reliable predictions of the strain hardening response of Hadfield steel and constitute an important guideline for the proper selection of them.Master Thesis Alüminyum 7068 Malzemesinin Mekanik Davranışlarının Hassas Olarak İncelenmesi ve Hasar Modelinin Araştırılması(Abdullah Gül Üniversitesi, 2018) Karaveli, Kadir Kaan; Karaveli, Kadir Kaan; Bal, BurakYüksek mukavemet, yüksek tokluk, düşük yoğunluk ve korozyon dirençliliğinin ümit vaat eden kombinasyonu, onlarca yıldır alüminyum (Al) alaşımlarını binalardan havacılık sektörüne çeşitli uygulamalarda tercih edilen malzeme haline getirmiştir. Özellikle son zamanlarda geliştirilen malzemelerden bir tanesi olan Al 7068 alaşımı, olağanüstü mekanik ve mekanik özelliklerinden dolayı savunma sanayinde ve otomobil sanayinde kullanılmaktadır. Bu yüksek lisans tezinde, Al 7068-T651 alaşımının mekanik tepkisi ve Johnson-Cook hasar modeli araştırılmıştır. Özellikle, maksimum, minimum ve ortalama sonuçları dikkate alarak farklı uygulama alanları için farklı Johnson-Cook hasar parametreleri belirlenmiştir. Bu hasar parametreleri doğru Sonlu Elemanlar Analizi simülasyonları için kullanılabilir. Hasar parametrelerinin belirlenmesinde, hem hadde yönünde hem de hadde yönüne dik olarak çentikli ve düzgün numuneler üzerinde çekme deneyleri yapılmıştır. Çentik yarıçapı, farklı gerilim üçeksenliliği değerlerini sağlamak için pürüzsüz, 0,4 mm, 0,8 mm ve 2 mm olarak seçildi ve bu gerilim üçeksenliliği değerlerinde mekanik malzemenin tepkisi gözlemlendi. Çekme testleri, doğru sonuçları elde etmek için yedi kez tekrarlandı. Kırık numunelerin son kesit alanları optik mikroskop ile hesaplandı. Gerilim üçeksenliliği faktörünün ve hadde yönünün Al 7068-T651 alaşımının mekanik özellikleri üzerindeki etkileri başarılı bir şekilde araştırılmıştır. Tüm hasar parametreleri Levenberg-Marquardt optimizasyon yöntemi ile hesaplandı. Sonuç olarak, minimum, ortalama ve maksimum eşdeğer gerinim değerlerine dayanan üç farklı Johnson-Cook hasar parametresi hesaplanmıştır. Bu Johnson-Cook hasar parametreleri, bir hesaplama tekniği olan ve bu çeşitli mühendislik problemlerinin yaklaşık çözümünü elde etmek için kullanılan sonlu elemanlar analizinde farklı uygulamaların doğru hasar simülasyonları için kullanılabilir.Article Citation - WoS: 22Citation - Scopus: 23Strain Rate and Hydrogen Effects on Crack Growth From a Notch in a Fe-High Steel Containing 1.1 Wt% Solute Carbon(Pergamon-Elsevier Science Ltd, 2020) Najam, Hina; Koyama, Motomichi; Bal, Burak; Akiyama, Eiji; Tsuzaki, KaneakiEffects of strain rate and hydrogen on crack propagation from a notch were investigated using a Fe-33Mn-1.1C steel by tension tests conducted at a cross head displacement speeds of 10(-2) and 10(-4) mm/s. Decreasing cross head displacement speed reduced the elongation by promoting intergranular crack initiation at the notch tip, whereas the crack propagation path was unaffected by the strain rate. Intergranular cracking in the studied steel was mainly caused by plasticity-driven mechanism of dynamic strain aging (DSA) and plasticity-driven damage along grain boundaries. With the introduction of hydrogen, decrease in yield strength due to cracking at the notch tip before yielding as well as reduction in elongation were observed. Coexistence of several hydrogen embrittlement mechanisms, such as hydrogen enhanced decohesion (HEDE) and hydrogen enhanced localized plasticity (HELP) were observed at and further away from the notch tip resulting in hydrogen assisted intergranular fracture and cracking which was the key reason behind the ductility reduction. (C) 2019 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved.Article Citation - WoS: 31Citation - Scopus: 31A Detailed Investigation of the Effect of Hydrogen on the Mechanical Response and Microstructure of Al 7075 Alloy Under Medium Strain Rate Impact Loading(Pergamon-Elsevier Science Ltd, 2020) Bal, Burak; Okdem, Bilge; Bayram, Ferdi Caner; Aydin, MuratEffects of hydrogen and temperature on impact response and corresponding microstructure of aluminum (Al) 7075 alloy were investigated under medium strain rate impact loading. The specimens were subjected to impact energy of 12 J and 25 J, corresponding to impact velocities of 2.13 m/s and 3.08 m/s, respectively. These energy levels were decided after a couple of impact tests with different impact energy values, such as 6 J, 10 J, 12 J, 25 J. The experiments were conducted at five different temperatures. Electrochemical charging method was used for hydrogen charging. Microstructural observations of hydrogen uncharged and hydrogen charged specimens were carried out by scanning electron microscope. Hydrogen changed the crack propagation behavior of Al 7075 alloy depending on the temperature. Coexistence of several hydrogen embrittlement mechanisms, such as hydrogen enhanced decohesion (HEDE) and hydrogen enhanced localized plasticity (HELP) were observed under impact loading. The impact response of Al 7075 was significantly deteriorated by the hydrogen charging and changing temperature affected the absorbed energy of hydrogen-charged specimens. In addition, molecular dynamics simulations were conducted to uncover the atomistic origin of hydrogen embrittlement mechanisms under impact loading. In particular, hydrogen decreased the cohesive energy and enhanced the average dislocation mobility. Therefore, the experimental results presented herein constitute an efficient guideline for the usage of Al alloys that are subject to impact loading in service in a wide range of temperatures. (C) 2020 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved.